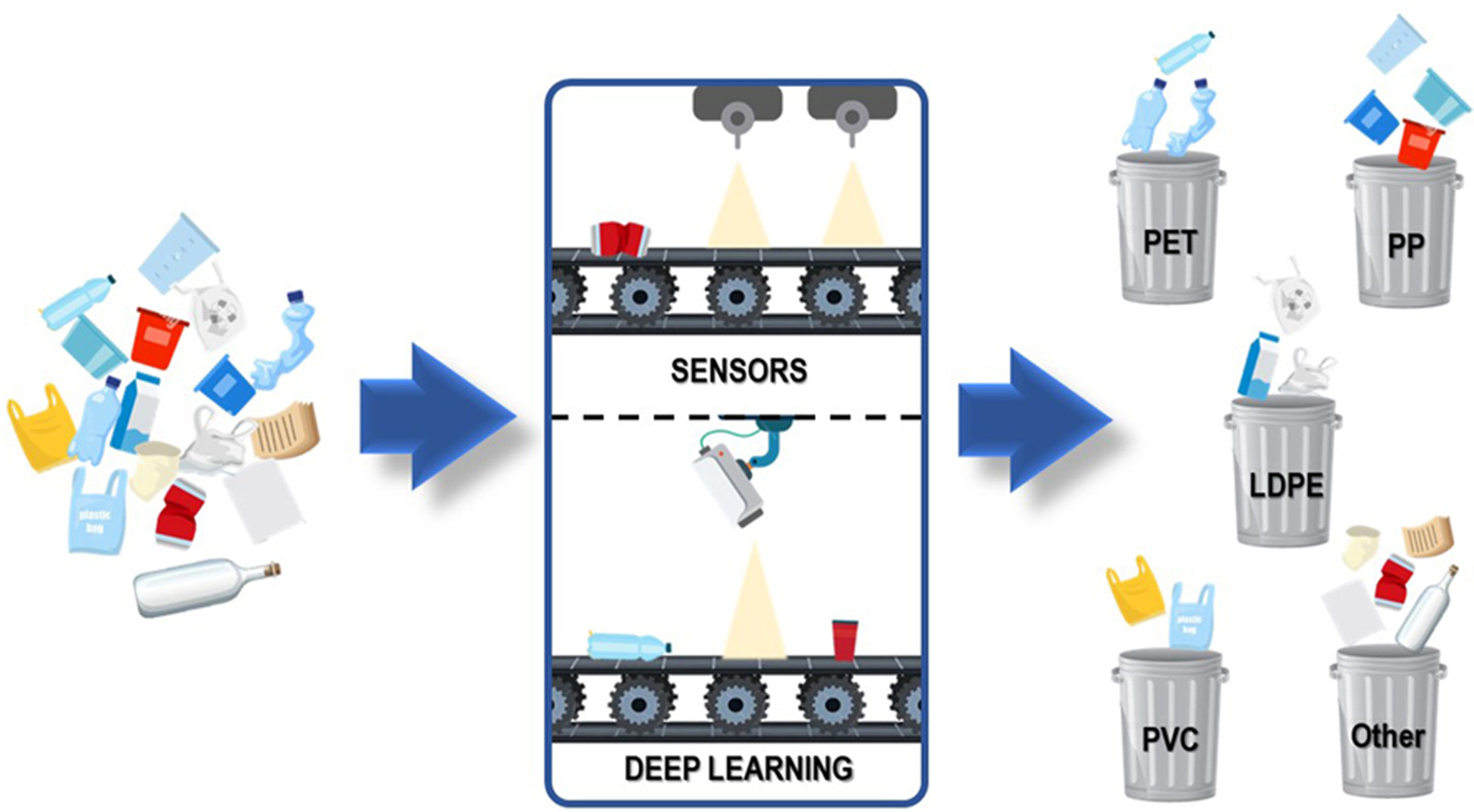

Plastic waste pollution is a challenging and complex issue caused mainly by high consumption of single-use plastics and the linear economy of “extract-make-use-throw”. Improvements in recycling efficiency, behaviour changes, circular business models, and a more precise waste management system are essential to reduce the volume of plastic waste. This paper proposes a simplified conceptual model for a smart plastic waste separation system based on sensor technology and deep learning (DL) to facilitate recovery and recycling. The proposed system could be applied either at the source (in a smart waste bins) or in a centralised sorting facility. Two smart separation systems have been investigated: i) the one utilising 6 sensors (near-infrared (NIR), humidity, temperature, CO2, CH4, and a laser profile sensor) and ii) the one with an RGB camera to separate packaging materials based on their composition, size, cleanliness, and appearance. Simulations with a case study showed that for a camera-based sorting, Inception-v3, a DL model based on convolution neural networks (CNN), achieved the best overall accuracy (78%) compared to ResNet-50, MobileNet-v2, and DenseNet-201. In addition, the separation resulted in a higher number of misclassified items in bins, as it focused solely on appearance rather than material composition. Sensor-based sorting faced limitations, particularly with dark colouration and organic matter entrapment. Combining the information from sensors and cameras could potentially mitigate the limitations of each individual method, thus resulting in higher purity of the separated fractions.